- Home

- About Us

- Products

- Workshop

- Customer visit

- News

- Contact Us

Views: 5 Author: Site Editor Publish Time: 2020-04-02 Origin: Site

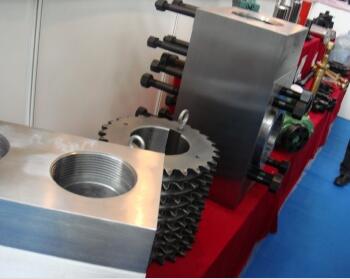

Mud Pump Module

Product Description

The Module comprises a plurality of laterally connected mud pump valve boxes, the mud pump valve box is mainly composed of a valve box main body, a bonnet pressure cylinder and a valve seat assembly, and the valve box main body comprises a suction valve box main body arranged in a direction and The main body of the valve box is discharged, the bottom end of the main body of the suction valve box is provided with a suction port, and the main body of the discharge valve box is provided with a discharge pipe, and each discharge pipe is connected by a flange sleeve.

The utility model has the advantages that the main body of the valve box is an independent structure, for example, the main body of the valve box is faulty and cannot be repaired, and only the main body of the split valve box is separately replaced, thereby saving cost, and each discharge pipe is connected through the flange sleeve, and only needs to be carried out at the faulty place. Disassembly and repair, easy to disassemble.

Among the mud pump accessories for oil drilling, the valve box is one of the key components, and its structural composition directly affects the use of the mud pump.

The structure of the commonly used mud pump valve box is generally three valve boxes arranged in series, and the main body of the suction valve box of the valve box main body and the main body of the discharge valve box are arranged in an upper and lower arrangement, and the discharge pipe of each valve box main body is integral, and cannot be separated. ], disassembly and assembly is inconvenient.

In the process of use, once the valve box fails, the main body of the suction valve box and the main body of the discharge valve box should be inspected as a whole, which is labor intensive and has a fault if it is sucked into the main body of the valve box or the main body of the discharge valve box. If it cannot be repaired, the entire valve box will be scrapped in total, which is very inconvenient.

Mud Pump Parts: A Few Facts

There are three basic different types of drilling mud pumps each with their own unique set of components and parts.

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure to the crankshaft. High piston load can lead to excessive pressure and crankshaft failure, if the components are not properly sourced.

Quintuplex: These pumps are perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well’s bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

Saigao offers high quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

we are F800 mud pump exporter and F1000 mud pump supplies,you can know it.